Project

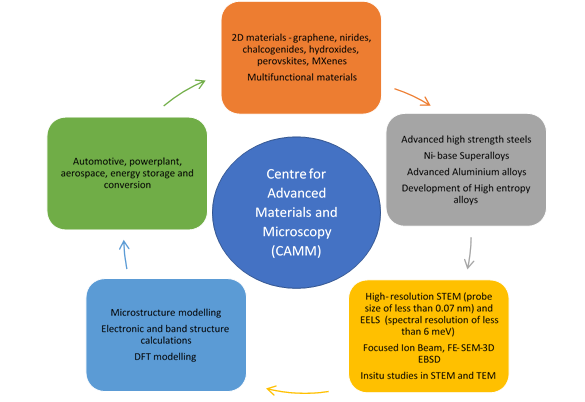

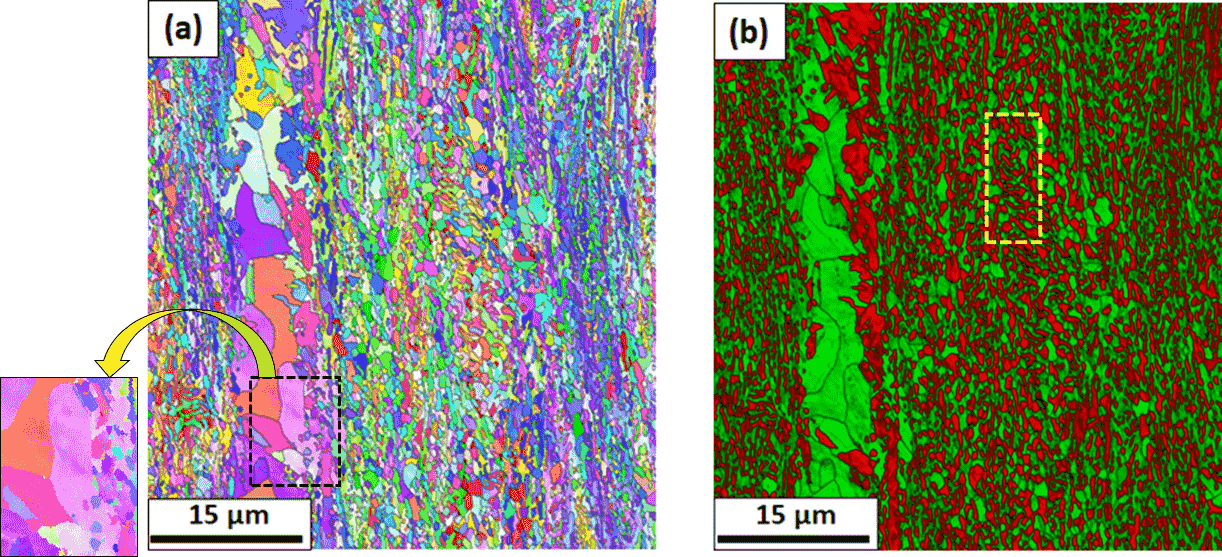

Advanced High Strength Steel (AHSS) : The center will design AHSS compositions based on computational thermodynamics and kinetics. The optimized compositions will be prepared through lab scale melting/casting. The deformation behavior, processing maps will be established using thermomechanical simulator. The microstructure and mechanical properties of these steels will be evaluated at quasi-static and high strain rates. Quantitative electron microscopy and spectroscopy (SEM-EBSD, STEM, APT) will be used to study the deformation mechanisms and their correlation to the microstructure and texture.

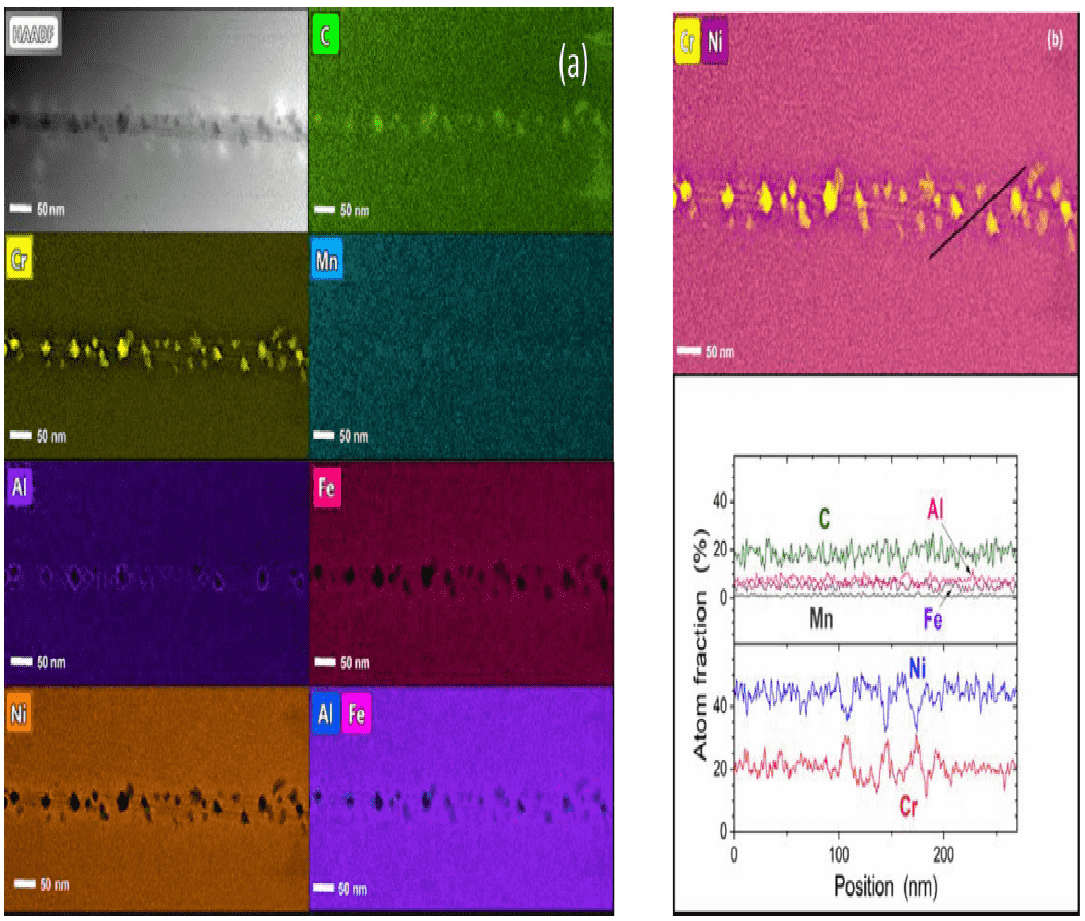

The center will engineer the grain boundary character in high temperature alloys to improve their creep, oxidation, and hot corrosion resistance. Evaluation of grain boundary character, grain boundary connectivity and microstructure using SEM-EBSD to establish the optimum grain boundary engineering (GBE) processing condition. Evaluation of creep, corrosion and oxidation behavior of the high-temperature alloys and establish the grain boundary network-property correlations.

Inverse Pole Figure (IPF) map

phase map of in a multiphase medium Mn steel developed using computational thermodynamics and kinetics approach

Grain boundary/interphase studies in complex engineering alloys

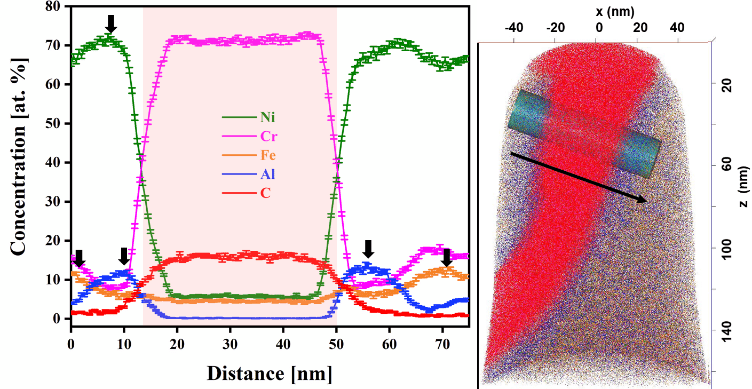

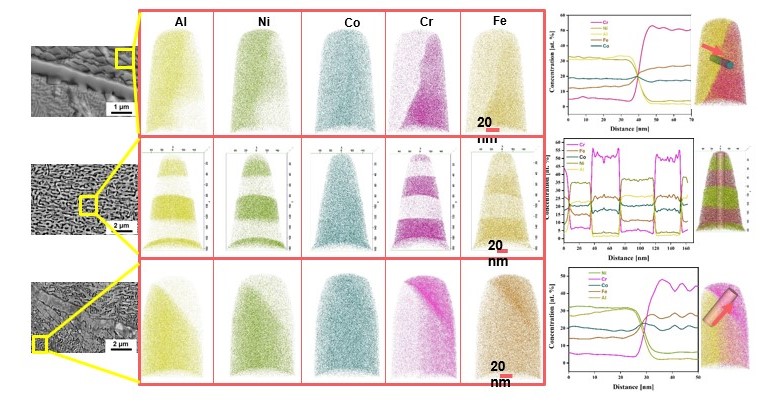

The center will address the specific objectives of understanding the grain boundary structure and segregation induced phase transformation at sub micron-scale and strain across the boundary or interphase in technologically important complex nickel base alloys using advanced Cs-corrected STEM and Chemistem technologies. Furthermore, an extensive study on the atomic-scale chemical analysis of ordered second phase, interphase and grain boundaries in new generation high temperature advanced aluminum alloys using STEM EDS and EELS. The coherency strain will be estimated through geometrical phase analysis of ordered second phase precipitates. The research work will also focus on the quantification of lattice distortion and carbon partition mechanisms in advanced high strength steels. X-ray synchrotron diffraction experiments will be used for this purpose through international collaboration.

STEM –EDS and APT analysis of grain boundary precipitation, phase transformation and segregation

Microscopic investigations on Advanced multifunctional materials:

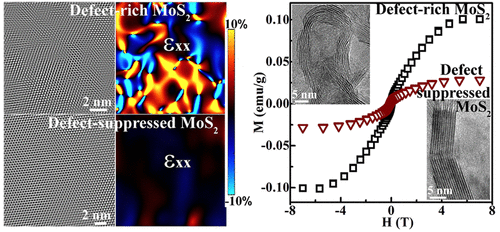

Many of functional materials such as multiferroic oxides, battery materials and solar cell devices contain numerous interfaces and domains. The functional properties are tailored by the key role played by these interfaces. Understanding of relations between the functions and properties of interfaces, including macroscopic morphologies, local atomic configurations, and chemical states, still have been a big challenge due to difficulties in characterization of individual interfaces. Using state-of-the-art microscopy analysis, we aim to evaluate morphology, atomic structure, and properties of interfaces in functional materials. Nanometer-scale imaging of magnetic, ferroelectric and photovoltaic perovskite thin films using scanning transmission electron microscopy will be the prime avenue for investigating the materials at the atomic scale. Aberration-corrected STEM enables imaging of magnetic fields in materials using differential phase contrast (DPC) with a resolution of 1 nm. This will enable highly correlated studies of the perovskites, giving a deeper understanding of these new phenomena. High-resolution microscopic studies on the perovskite devices suitable for optical and photovoltaic studies will be made from the perspective of improving the quantum efficiency of the devices. DPC method can be extended to imaging of static and dynamic magnetic properties of the materials with nanometer resolution.

Defects, shown in the distribution of strain obtained from the high-resolution TEM imaging, play a significant role in enhancing the magnetic properties of 2D MoS2 nanosheets.

Correlating synthesis methods of MXene 2D energy storage materials with their local atomic and electronic structures

Objective

Methodology

Objective of the project is to establish correlation between synthesis parameters with local atomic and electronic structure will help to produce MXene customized for different energy storage applications.

Deliverables after 2nd years:

- Synthesis of different MAX phases and corresponding MXenes with varying synthesis parameters

- Identification of atomic columns comprising light elements using modified NCSI method and characterization of point defects at atomic scale will be using inline 3D holography

Calphad based approach to alloy design

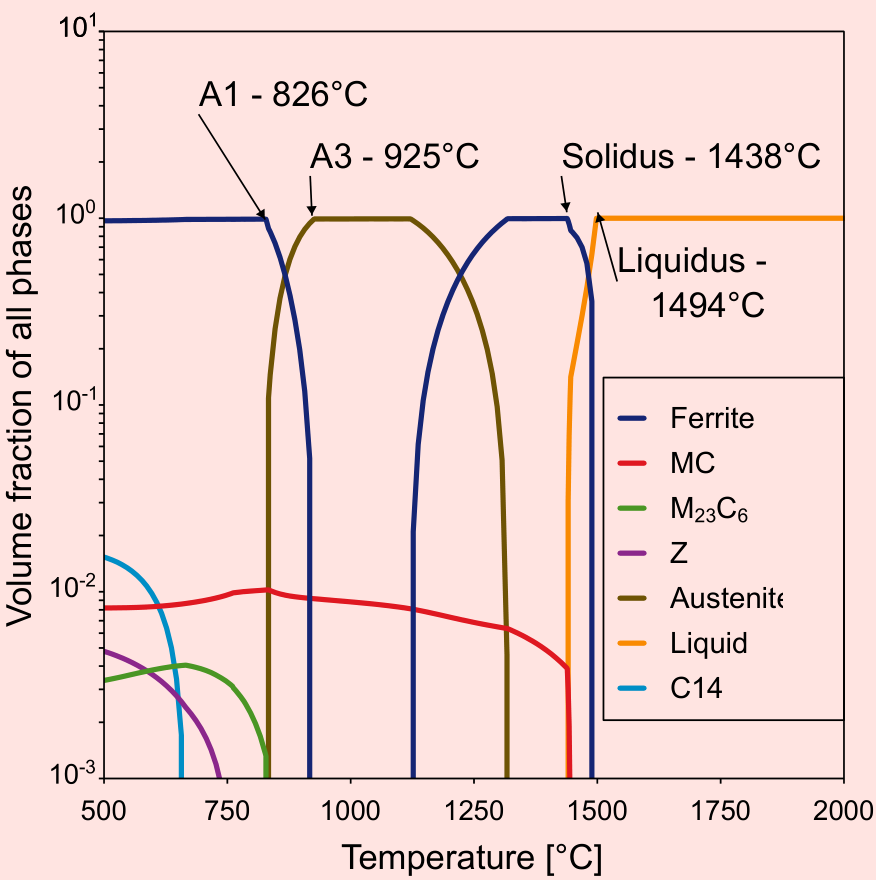

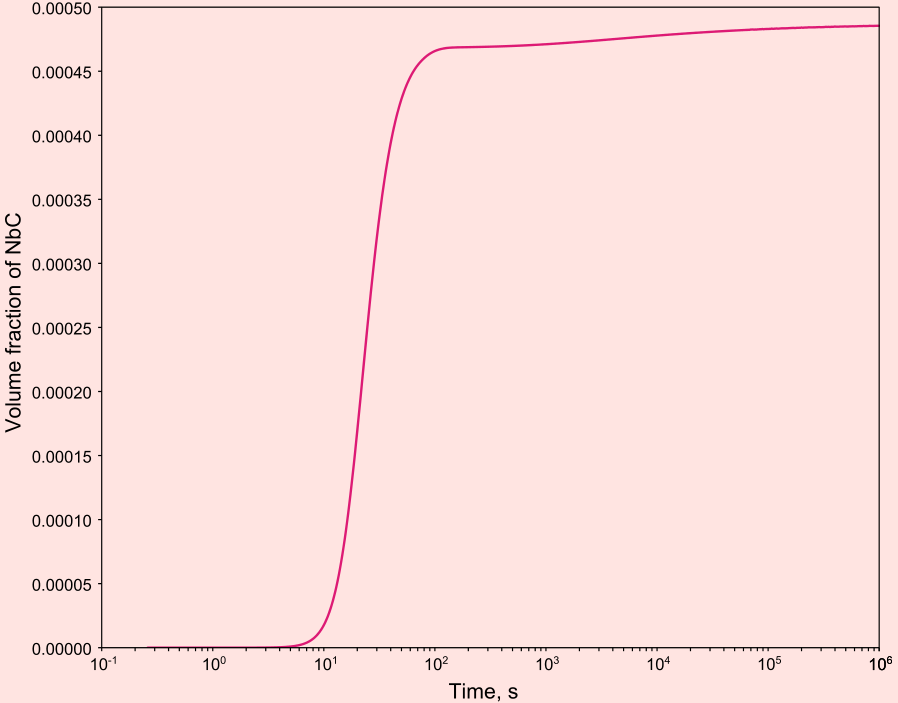

Computational thermodynamics provides an alternative approach that allows one to obtain multicomponent information from knowledge of lower-order systems (not exceeding ternary). It uses thermodynamic models based on the physical and crystallographic data of the phases. Such an approach, better known as CALPHAD, describes the Gibbs energy of each phase present in a multicomponent system utilizing mathematical functions of the temperature and composition. These functions (stored in a database), combined with Gibbs energy minimization software such as Pandat and Thermo-Calc, can compute phase equilibrium and thermochemical properties at any desired composition and temperature, even in regimes where there are no experimental data. Combining thermodynamic databases with mobility databases allows one to make kinetic simulation of diffusion-controlled phase transformations in engineering materials. With the aid of computational thermodynamics and kinetics, we plan to develop new grades of 3rd generation Advanced High Strength Steel (AHSS) having tensile strength and uniform elongation exceeding 1000 MPa and 20%, respectively.

Tuning the chemistry, stacking fault energy and phase fraction through first-principles, computational thermodynamics and kinetics for design of advanced high strength steels, Computation of phase equilibria, Kinetic simulation of phase transformations.

We use first-principles atomistic modeling to complement the analysis of atomic resolution microscopy images from STEM. First-principles modeling based on electronic structure of materials provides the opportunity to establish processing- structure-property relations of materials directly from established quantum mechanical laws without making assumptions such as empirical or fitted parameters. Electronic structure based modeling is particularly suitable for exploring properties of nano-materials (best characterized by STEM) that have vast chemical and configurational space. Atomic structure information provided by STEM for bulk of the materials when complemented by atomistic modeling can be used to understand stresses, and thermodynamic stability of phases present. Atomic structure information of ceramic interface from STEM can be further refined by atomistic modeling to understand anion terminations.

Atomic Scale Microscopy towards Understanding and Design of Complex Engineered High entropy alloys

HEAs are being considered for numerous structural and functional applications due to their attractive properties. The design of the composition and microstructure of HEAs for various applications needs a thorough understanding of distribution of elements through atomic scale microscopy. There is a need to study dislocation-solute interactions in HEAs through in-situ microscopy at small scale to design desirable microstructures for specific applications. Modeling to predict the microstructure of HEAs and the use AI/ML can play a significant role in designing tailored HEAs.

Expected deliverables of the research

- CAMM will design, develop and synthesize the contemporary advanced materials

- This centre will strive to achieve international visibility through high-quality research output as well as from the collaborative research programs

- The centre will organize thematic workshops, conferences, training programs and summer and winter schools to disseminate the knowledge

- The CAMM will impart training in theoretical, experimental and modelling aspects of materials and the microscopy techniques using contemporary interdisciplinary research problems to a significant number of doctoral as well as post-doctoral students.

- CAMM will strive to collaborate with leading groups in the world

Current status

Recent Publications:

Rohini Sanikop, Nitika Arya, Viswanath Balakrishnan, Chandran Sudakar, “Charge Pumping by Contact Electrification Using Electrostatic Force Microscopy in Bi- and Tri-Layered MoS2 Nanosheets”, The Journal of Physical Chemistry, Part C: Energy, Materials, and Catalysis, (May 2021) (accepted) doi

S. Nandy, Pavana S. V. Mocherla, E. Abdelhamid, B. Nadgorny, R. Naik and C. Sudakar, Coexistence of large negative and positive magnetodielectric response in Bi1-xCaxFe1-yTiyO3-d nanoparticle ceramics, Phys. Rev. B, 103, (2021) 184406. doi

A.C. Dakshinamurthy, C. Sudakar, Bandgap engineering and sublattice distortion driven bandgap bowing in Cs2Ag1-xNaxBiCl6 double perovskites, Applied Physics Letters, 118 (2021) 131902. doi (Editor’s Pick)

Y. Lokeswararao, M. Viji, A.K. Budumuru, C. Sudakar, Enabling high-rate capability by combining sol-gel synthesis and solid-state reaction with PTFE of 4.2 V cathode material LiVPO4F/C, Materials Today Communications 27 (2021) 102435 doi

M. Viji, A.K. Budumuru, V. Hebbar, S. Gautam, K.H. Chae, C. Sudakar, Influence of Morphology and Compositional Mixing on the Electrochemical Performance of Li-Rich Layered Oxides Derived from Nanoplatelet-Shaped Transition Metal Oxide-Hydroxide Precursors, Energy and Fuels, 35(5) (2021) 4533-4549. doi

P. Ilaiyaraja, V. Sharma, A. C Dakshinamurthy, T.K. Das, C. Sudakar, Fabrication of metal chalcogenide thin films by a facile thermolysis process under air ambient using metal-3-mercaptopropionic acid complex, Materials Research Bulletin, 141 (2021) 111346. doi

Magham, H.S.R., Maheswari, N., Dinesh, K., Vijayaraghavan, L., Sankaran, S. and Padmanabhan, K.A. (2021), On a New Two-Step Air Cooling Method Following Thermomechanically Controlled Rolling: Microstructural Evolution and Mechanical Properties of a High-Strength Multiphase Medium Carbon Microalloyed Steel. steel research int., 92: 2000563. doi

Partha Sarathi De, Amol Vuppuluri, Subramanya Sarma, V. and Srikanth Vedantam, A physically based model of the effect of recovery and clustering on recrystallization kinetics, Journal of Materials Science (2021), 56, 7082-7093. doi

Achintya Kumar Patra, Athreya, C. N., Sumantra Mandal, Hari Kumar, K.C., Subramanya Sarma, V. High strength-high ductility medium Mn steel obtained through CALPHAD based alloy design and thermomechanical processing, Materials Science and Engineering (A) (2021), 810, 140756. doi

Bhuyan, P. Paliwal, M. Subramanya Sarma, V. de Boer, B. Mitra, R. Mandal, S. Precipitate evolution during aging and its individual role on high-temperature hot corrosion response in Alloy 617, Journal of Alloys and Compounds, 2021, doi

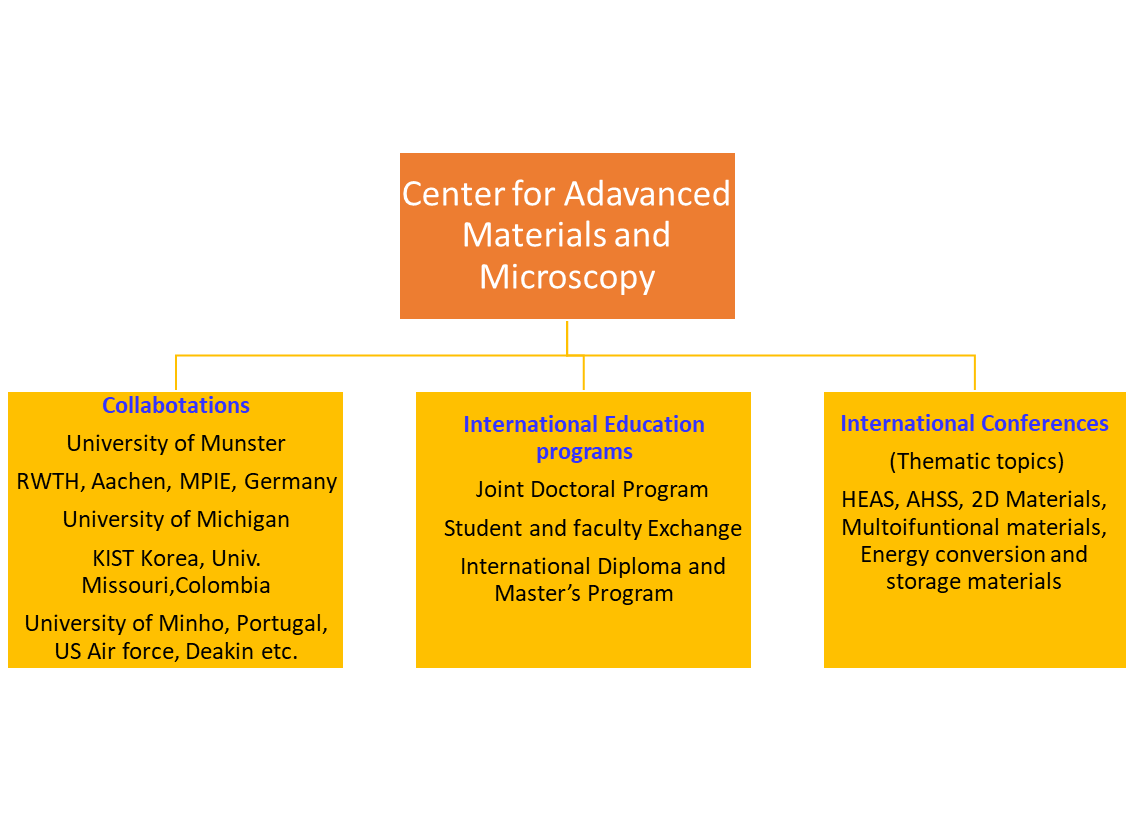

Collaborations

Collaborators

- Prof. Jeno Gubicza, Eotvos Lorand University, Hungary,Webiste: link

- Prof. Martin Heilmaier, KIT, Germany, link

- Prof. Greg Rohrer, CMU, USA, link

- Prof. Joachim Mayer, Aachen University, Germany, link

- Prof. Gerhard Wilde and Dr. Sergiy Divinski, University of Muenster, Germany, link

- Prof. Hamish Fraser and Dr. Babu Viswanathan, University of Ohio state, USA, link

- Prof. Carl Boehlert, University of Michigan, USA, link

- Prof. Keun Hwa Chae (KIST, South Korea), link

- Prof. Rick Ubic and Dr. Karthick (Boise State Univ.), link

- Prof. Ratna Naik, (Wayne State University) link

- Prof. Boris Nadgorny, (Wayne State University) link

- Prof Deepak Dubal, Queensland University of Technology, link

External international site links for project

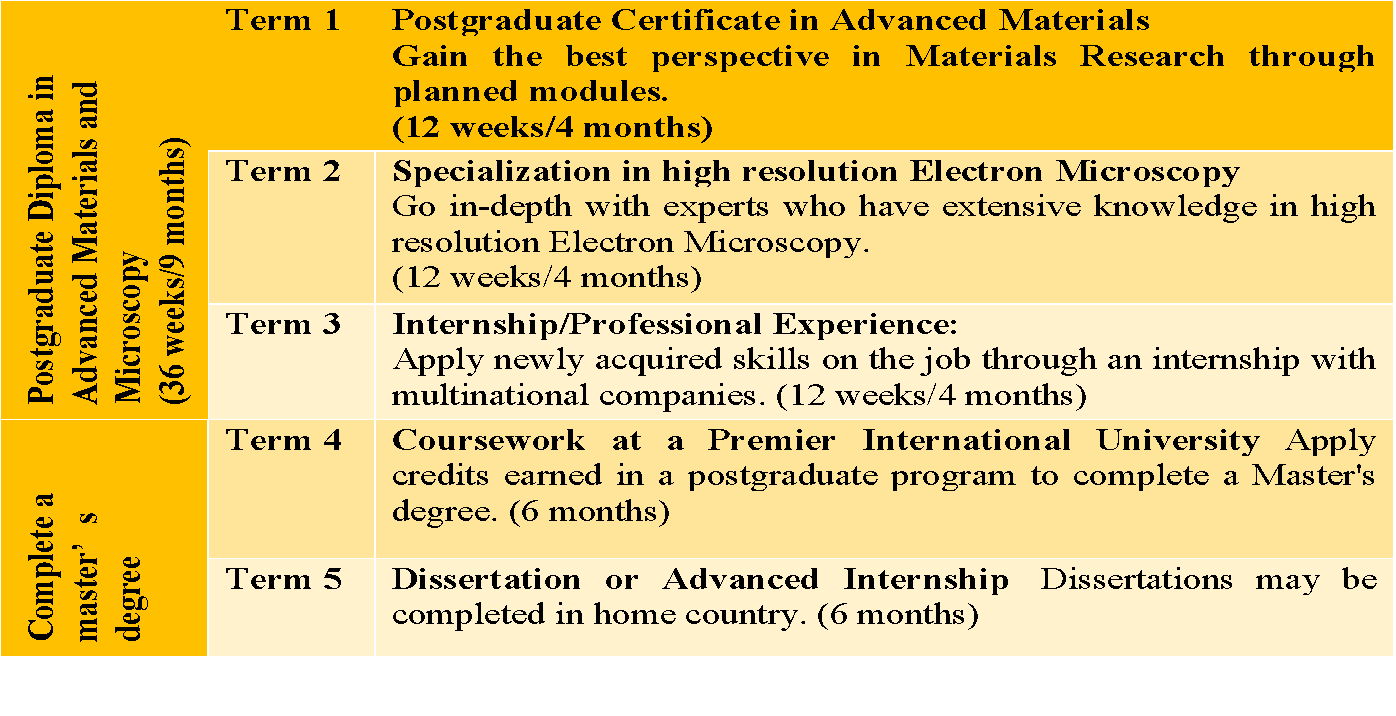

International education programs

-

We are planning to conduct monthly webinars. We will conduct two workshop/conference in near future. International conferences on the thematic topics of advanced materials such as high entropy alloys, advanced high-strength steels and Ni-based superalloys, 2D materials, Multifunctional materials, energy conversion and energy storage materials, Electron microscopy will be organized by the centre.

-

Plans to initiate program to offer postgraduate Certificate courses on Advanced Materials and Microscopy is in pipeline.

Societal impact

Next generation transportation requires high strength, light-weight materials to improve performance and reduce fuel consumption, cost and carbon emissions. The development of high strength and low cost steels envisaged in this proposal will play an important role in bringing down the emission and contributing to society. The interactions with the steel industry proposed as part Next-generation will help in making Indian steel industry competitive in the global market. It may be noted that India is already the second-largest steel producer in the world and the develop low-cost end steels will attract more OEMs to set up their upstream manufacturing and production processes in India thus contributing to the Make-in-India paradigm. The development of HEAs and grain boundary engineered high-temperature materials that are being projected in this project are expected to significantly improve the efficiency of power plants and aero engines. This will have a positive impact on the transportation and energy sector, resulting in reduced emissions, and contribute to society.

Modern batteries have revolutionized electronic devices. Next-generation battery materials developed with a focus to include high energy density with good cyclability. Such materials will have a tremendous societal impact in enabling increased driving range for electric cars. From Indian household perspective batteries with longer life and lower price can provide power to homes which are unreachable through grid lines. Advanced materials research relevant to solar cell materials will enable developing a new generation solar cell that has the potential to complement silicon solar cells to provide Indian households with abundant and affordable energy.

A large number of graduate students, postgraduates and post-docs will be trained on the sophisticated microscopy facilities. The training on the state-of-the-art facilities given to the students, researchers and trainees will imbibe critical thinking skills and lead them through the avenues to access skilled jobs. This, in turn will provide employment and career opportunities for a large pool of highly skilled personnel.

Sustenance statement

A multifaceted strategic approach will be used to sustain the centre’s activities after the five year of support from the two phases of IoE mode. With the application-oriented research and development activities nucleated and grown in the centre, the members will be able to bring industry-relevant projects, attract global and local consultancy, commit to complete work outsourced by industry, offer services on charge basis for small and medical scale industries, academia, etc., offer user-specific programs to industry professionals, offer training programs to academics through workshops and short-term courses on sophisticated state-of-the-art instruments. The centre will attract global universities to become a part of it and enhance the visibility on improving the investment from international players. The centre will be helping private and public institutions and universities in developing specialized courses on advanced engineering materials and microscopic techniques through consultancy mode. There is a lot of demand from Indian industries, R&D labs and multinational companies on microscopy and related services even with the existing facilities. We expect the establishment of the will attract a large number of these players to sign MoU to form a consortium which will further enable self-sustenance of the center. As mentioned above, several industries are expected to support this activity. The investigator already has completed some projects and has some ongoing projects with industries in this field. The project will provide catalytic support for these industrial collaborations. In future, the CoE would have strong support from industry and Govt R&D labs for its sustenance.

Technical/ Scientific Progress

New work done in the project

Identifying the suitable medium for long duration storage of Ti2CTx MXene

Recently, 2D material MXene gained significant attention due to its unique properties like chemical diversity, hydrophilicity, 2D morphology, metallic conductivity, etc. Inspite of the promising properties of MXenes, these materials are not gaining momentum in various applications because of their poor chemical or oxidation stability. Earlier reports stated that organic solvents with low temperature storage could prevent the oxidation of MXene flakes due to less number of dissolved oxygen molecules in the solvents. Till now, Ti3C2Tx MXene is the mostly investigated material due to its high capacitance and excellent conductivity. In this regard, Ti2CTx MXene also delivers comparable electrical and electrochemical properties like Ti3CTx, but is still getting less attention due to availability of suitable storage medium. To address this issue, this present study reports the suitable medium for preventing or delaying the degradation or oxidation of Ti2CTx MXene. Herein, Ti2CTx MXene was dispersed in different solvents for a duration of 3 months at ambient and freezing conditions and characterized thereafter using XRD, Raman, SEM, TEM and XPS techniques. The results suggest that the suitable medium to store Ti2CTx MXene for 3 months is IPA or DMSO at -20°C or Water at -80°C.

Infrastructure developments

Electrochemical Workstation, 4 point probe electrical resistivity measurement, protable ball mill.

Output

Identifying the suitable medium for long duration storage of Ti2CTx MXene, Chiranjit Roy, Subhra Kanti De, Pritam Banerjee, Soumen Pradhan, Somnath Bhattacharyya, Chemistry of Materials, communicated.