Project

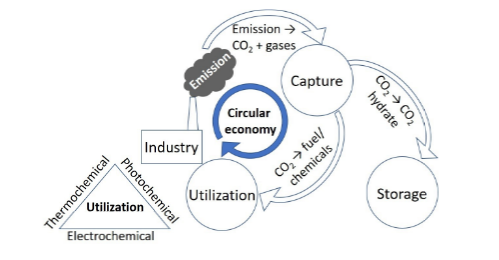

The CCUS lab at IIT Madras brings together a large interdisciplinary group of experts from the institute and its international partners to intensify research efforts and to make technological breakthroughs that would enable CO2 capture and separation from flue gas like mixtures, its utilization to produce liquid fuels like methanol or intermediate platform chemicals like syngas (CO + H2), and its long-term storage under the ocean beds.

Schematic illustration of carbon dioxide capture, utilization and storage strategies.

CO2 capture and separation from gaseous mixtures, its utilization to produce liquid fuels like methanol or intermediate platform chemicals like syngas (CO + H2) or upcycling to any value-added product and its long-term sequestration or storage, are widely accepted means to decarbonization. Intensification of fundamental and applied research in each of these directions with focus on translational technological breakthroughs to scale upwards on the technological readiness levels is a critical need of the hour. Rapid deployment of such technologies will enable zero emission, carbon neutral operation of our industries and also to meet the nation’s global commitment to drastically reduce our greenhouse gas emission intensity by the end of this decade. Addressing the current scientific and technological challenges in each of these domains require concerted efforts of interdisciplinary teams of academic researchers, industrial partners and technocrats. The CCUS lab at IIT Madras brings together a large interdisciplinary group of experts from the institute and its international and industrial partners to intensify research efforts and to make technological breakthroughs in each of the verticals of CCUS.

Carbon dioxide capture and separation

The first technological challenge in CCUS is the separation of carbon dioxide from the industrial exhaust gases, which typically is a mixture of gases including CO2, H2O vapors, O2, NOx, SOx, together with particulate matter. Solvent-free CO2 capture and separation technologies, where selective adsorption and separation of CO2 on solid adsorbent materials, is intensely researched across the globe. The CCUS lab will focus on developing high performance metal-organic framework and polymer-based absorbents for selective capture and separation of CO2 from the mixture of gases. Further, scale up of synthesis of such materials and scale out of systems for practical implementation will be taken up.

Phase-1 of the project aims to leverage the existing capabilities to analyze the systems for conditions relevant to CO2 separation. In parallel, facilities for high-throughput analysis of materials for multicomponent gas mixtures and screening of materials with desired stability, recyclability, capacity, and selectivity towards separation will also be set up. The team will exploit high throughput and detailed experimental analysis, molecular and multiscale simulations, and principles of machine learning and computational materials design in developing materials and systems for efficient

separation of CO2 from gaseous mixtures.

The overall objective of the team is to design and develop practically deployable porous materials, polymers and their composites and demonstrate the operation of adsorption based systems for CO2 separation from mixture of industrial gases. Carbon dioxide utilization:

Following the separation, one of the biggest challenges lies in efficient utilization of the separated CO2 as a feedstock to produce chemicals and fuels. Electrochemical, photochemical, photoelectrochemical, and thermocatalytic routes for the conversion of CO2 to fuels and other value-added products have been demonstrated. The CCUS team will explore both the thermocatalytic and photoelectrochemical/electrochemical routes of CO2 reduction to liquid and gaseous fuels /chemical feedstock.

Thermocatalytic conversion of CO2 to fuels/ chemicals:

With global interest in ‘gas to liquid’ technologies and in particular, ‘emissions to liquid’ technologies, the race is on to perfect the conversion of CO2 to liquids. One of the targets of the CCUS lab is developing the framework for technology development for thermocatalytic conversion of CO2 to methanol. The process revolves around the reduction of CO2 with hydrogen on multifunctional catalysts under high temperatures and pressures.

Phase-1 of the project aims to set up experimental facilities for the catalytic hydrogenation of CO2 to methanol on a multicomponent catalyst. During this period, facilities for carrying our operando spectroscopic analysis of the surface catalytic reactions will also be established. An approach integrating molecular simulations, catalytic experiments, operando spectroscopic analysis and kinetic modelling will be adopted to optimize the production of liquid fuels from CO2.

The overall objective of the team is to design and develop an optimum multifunctional catalyst and catalytic reactor, and to demonstrate and its optimum operation for efficient production of methanol from CO2.

Photoelectrochemical conversion of CO2 to fuels/ chemicals

Harnessing the potential of solar energy, photoelectrochemical reduction of CO2 to fuels and chemicals is an alternative to its thermocatalytic reduction. The CCUS lab will incorporate the state-of-the-art catalytic materials that offer high selectivity to the desired product into judiciously designed photoelectrochemical device architectures that enable enhanced efficiency and device stability. As a maturing technology with commercial potential, the CCUS lab will also focus on design and fabrication of high efficiency solar powered CO2 electrolyzer stacks to produce syngas (CO + H2). As a versatile platform for a wide range of chemicals, syngas production in this route is a step in the direction of Power to Chemicals.

Phase-1 of the project aims to 1) design and develop stable catalytic materials with high selectivity to the desired product, 2) develop photoelectrochemical systems for kinetics analysis and 3) to develop multiscale computational models that will enable system design and optimization. Phase 1 of the project will focus on developing a solar-powered CO2 electrolyzer that can produce syngas, which can further be used for methanol production.

One of the objectives of the team is to design and develop high performance catalysts and novel device architectures and demonstrate their integration for high performance in photoelectrochemical reduction of CO2 to chemicals. The team also envisions demonstration of scalable performance of solar powered CO2 electrolyzer devices for near future deployment.

Carbon dioxide storage in deep ocean as hydrates

With a vast coastline containing naturally formed methane hydrates, our ocean beds hold potential for long term storage of captured CO2. Since CO2 hydrates are thermodynamically more stable than methane hydrates, investigations on the formation kinetics and stability of the hydrates under typical sub-oceanic conditions to ascertain the technical feasibility of the injection of CO2 deep inside the oceanic sediments for storage as hydrates will be conducted. Phase-1 of the project will use a combination of molecular simulations and experiments to assess the potential for pumping liquid /gaseous /supercritical CO2 into the deep ocean to convert it to solid hydrates which would remain stable in geological time scales. Additionally, to assess the economic feasibility of this process, the entire CO2 value chain, from source to sequestration site would be modelled to estimate the cost of sequestration. The overall objective of the team is the demonstrate the techno-economic feasibility of long- term storage of CO2 under deep ocean beds in the form hydrates.

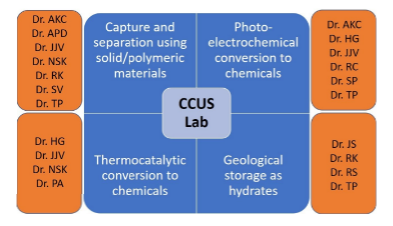

Research themes under the CCUS Laboratory and the corresponding interdisciplinary teams from the Department of Chemical Engineering at IITM

Expected deliverables of the research

Separation of CO2 from mixture of gases

- Screened and selected set of MOFs and polymers that are stable, with potential for scalable synthesis and are highly selective for CO2 separation from gas mixtures under realistic conditions.

- Lab scale demonstration of separation of CO2 from gaseous mixtures using these materials.

- Design and development of scaled out systems for practical application.

- Computational material and system design and optimization for enhanced performance.

Thermocatalytic conversion of CO2 dioxide to fuels

- Surface structure of multifunctional catalyst for CO2 hydrogenation to methanol under the harsh operating conditions.

- CO2 hydrogenation reaction mechanisms and detailed reaction network with energetics on these multifunctional catalysts.

- Lab scale demonstration of selective methanol synthesis and the potential for pilot scale studies

- Hierarchical kinetic models for optimization of reactor operation.

Photoelectrochemical conversion of CO2 to fuels

- Intrinsically stable, highly efficient, and selective catalytic materials for electrochemical reduction of CO2 to fuels

- Experimental setup and designs for accurate kinetics investigations

- Multiscale computational models for device performance prediction and optimization

- Demonstration of syngas production from large area solar driven CO2 electrolyzer with optimized high-performance electrodes.

- Demonstration of syngas production in scaled out high performance electrolyzer comprising stacks of devices.

CO2 storage as hydrates in the deep ocean

- Lab scale demonstration of CO2 hydrate formation at conditions typically prevailing in deep ocean beds.

- Identification and design of additive for enhanced hydrate formation

- Models for predicting kinetics of formation and storage capacity in real sub-oceanic environment.

- Model for the entire CO2 value chain from source to sequestration site to estimate the cost of sequestration.

Current status

Currently, equipment procurement and preliminary computational work is underway.

Collaborations

International education programs, conferences/seminar/webinar links

- We are in deep discussions regarding putting together two things:

- Energy Seminar Series (a monthly talk by International Experts)

- Consortium of Academic/Industrial Partners

- Energy Seminar Series (a monthly talk by International Experts)

Industrial collaborations

Will confirm once our talks materialise into concrete terms If there are any industrial partners already identified, information about such partners

We have outreach underway as indicated below:

- GAIL (two related projects are currently funded by them)

- IOCL, India (proposal is in approval process)

- St. Gobain, Chennai (in discussion phase)

- Exxon Mobil, USA (in discussion phase)

Societal impact

Carbon emissions due to burning fossil fuels pollute the environment and create serious health impact and climate change. On one side, there is a demand for energy due to the population and economic growth in developing countries like India, and on the other side, there is a push for clean energy to reduce the carbon emissions. To flatten the anthropogenic carbon emission, by 2042, India requires nearly 490 GW of power from renewable green energy. Even with aggressive renewable energy policies, it will be a hard target to reach considering the fact that renewables, especially solar energy, require completely new energy infrastructure. Until the renewable energy technologies attain significant maturity and attain en masse, to utilize the existing power infrastructure, and to cope with energy/economic demands, fossil fuels shall continue to exist if the emitted carbon dioxide can be captured and stored or utilized to generate value-added chemicals. The CCUS lab aims to develop cutting-edge materials and technologies for capturing and storing the carbon dioxide or converting them to useful chemical/fuels. The Centre’s direction is very much aligned with the climate goals signed by India at Paris Climate Agreement and we are committed to develop technologies to sustain a healthy environment, economy and energy demands.

Sustenance statement

The CCUS lab has a target to explore both government and industry funding sources to sustain the research activities. The planned activities are expected to create indigenous products for carbon dioxide conversion to fuels, and by the way of technology transfer or creating start-ups through Make in India initiatives/funding, the activities of the centre will be sustained. As the centre is well equipped with highly interdisciplinary experimental and simulation experts and the state-of-the-art facilities, the centre will apply for funding through Government of India’s funding through Mission Innovation programme. Since the proposed activities of centre are a part of social responsibility programme, efforts will be made to attract funding from CSR grants to deploy/test carbon dioxide electrolyers/reactors.