Project

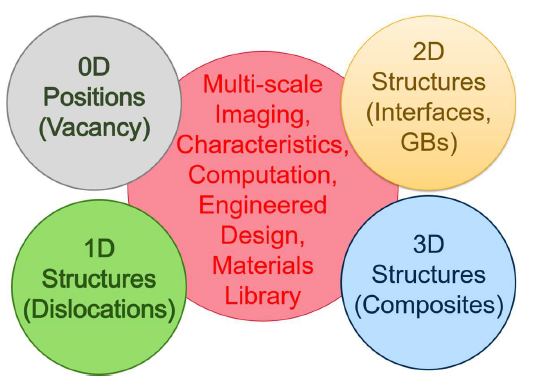

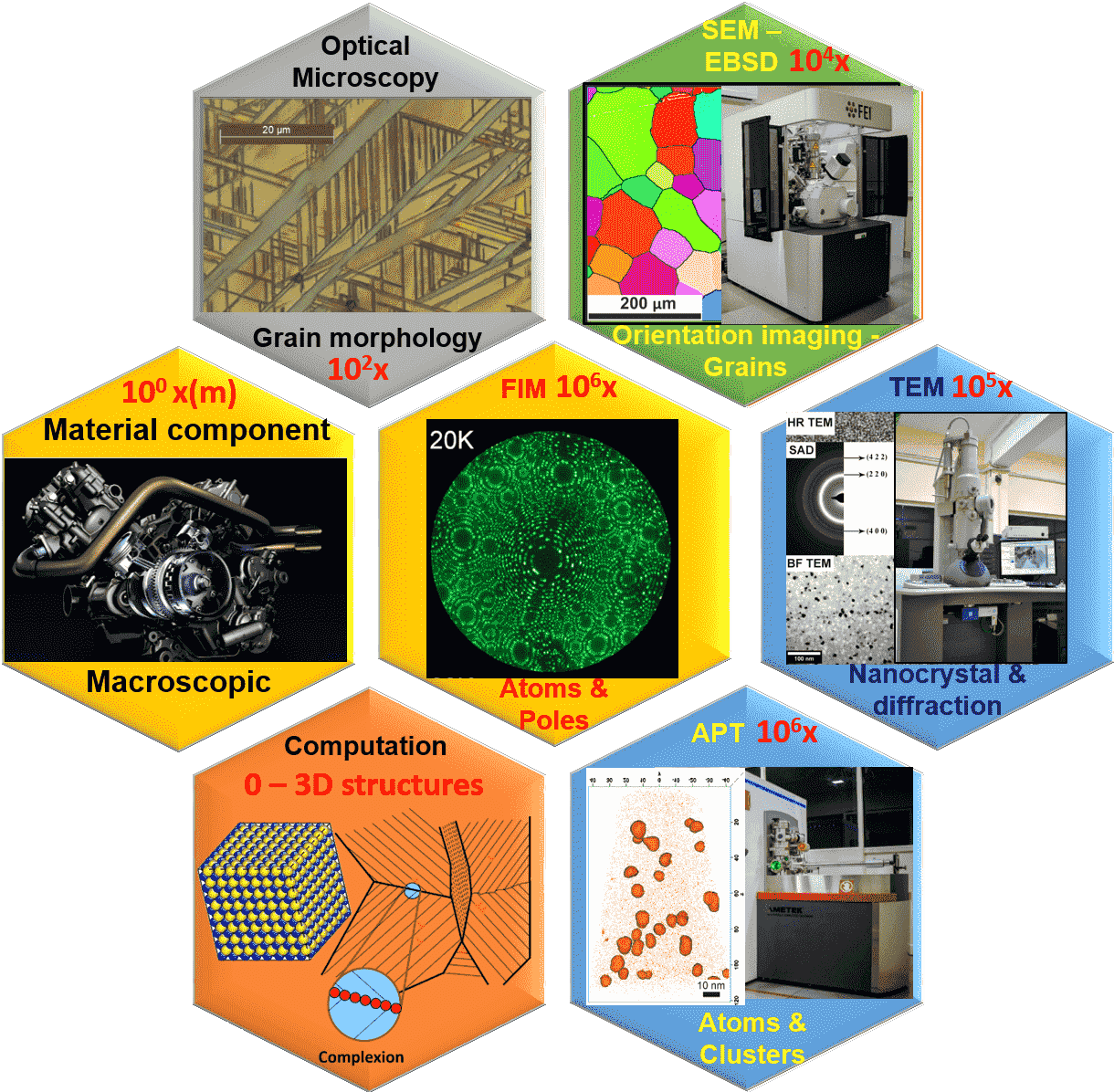

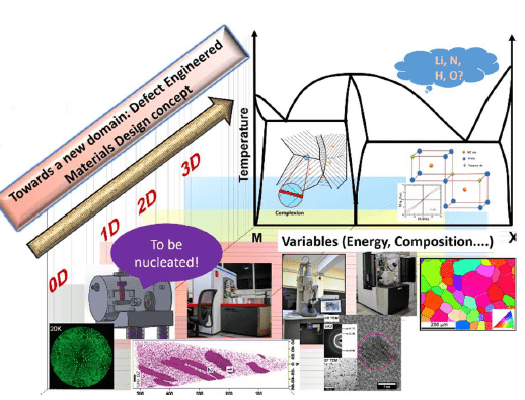

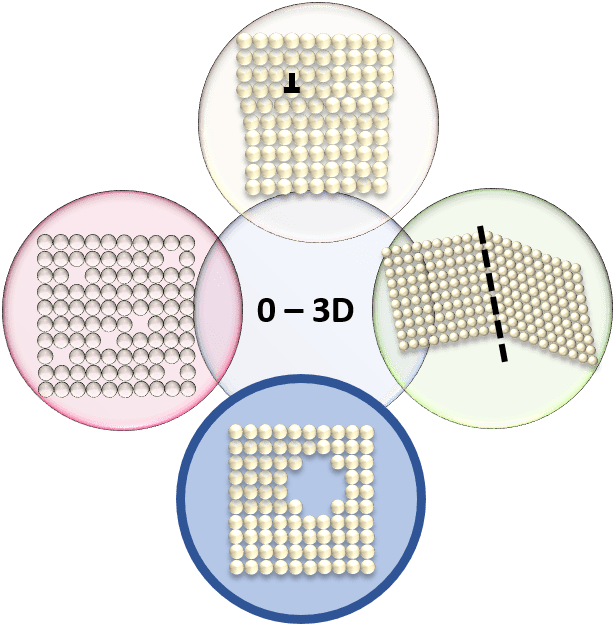

To address the requirement of comprehensive characterization of materials and their defect structures, thereby enabling the understanding of their properties, the following objectives are planned,

- Custom-design and develop “Field-Ion Microscope” which will enable imaging of individual atoms in materials.

- Investigations on wide range of materials ranging from

- Magnetic nanoparticles, Nanostructured materials by wire-explosion.

- Additive manufactured and structural materials - eg. Steels, Al, Ti and High Entropy alloys.

- Energy and Electronic materials – eg. those used in Li-ion batteries and Chalcogenide based phase change materials for data storage.

- Materials behaviour in varied environments – eg. Hydrogen embrittlement and irradiation effects.

will be carried out correlatively with experimental efforts complementing theoretical predictions, towards developing a comprehensive materials defect database for future design of high performance material systems.

- Development of experimental and computational methods to study in-situ atomic-scale effects in defect-structures subjected to service-life conditions.

Expected deliverables of the research

- Establishment of unqiue atomic-scale characterisation facility namely, Field Ion Microscope.

- Research publication in high impact journals (10+ impact) with the envisaed correaltive microscopy methodology while utilizing existing sophisticated facilities.

- Exclusive man power development with trained skill sets on advaced characterization and computational techniques.

- International and national collaborations with organization of international conferences.

- Industrial collaborations and commercialization of the developed correlative microscopy tools.

Current status

- Custom-designed correlative microscopy tool kit is under testing stage

- Design and manufacture of the correlative microscopy tool has been completed.

- Engineering drawing of the envisaged FIM setup has been completed and is under construction accordingly.

Collaborations

International Collaborations

- Prof. Rhys Jones, Monash University, Australia

- Prof. Dierk Raabe, Max-Planck-Institute für Eisenfischung GmbH, Germany

- Prof. Jochen Schneider, RWTH Aachen University, Germany

- Prof. Pyuck-pa Choi, Korean Advanced Institute of Science and Technology (KAIST), South Korea

- Dr. María González Viada, CIEMAT, Madrid, Spain

- Prof. Matsumi Noriyoshi JAIST, Japan

- Prof. Philip Eisenlohr, Michigan State University, USA

- Prof. A. V. Morozkin, Moscow Lomonosov state university, Moscow, Russia

- Dr. Christian Haase, RWTH Aachen University, Germany

- Prof. Vincent Taupin, University of Lorraine/CNRS, Metz, France

- Dr. Oksana Glovenia, Ural University, Russia.

Industrial collaborations

- Wipro 3D

- Inductotherm India Pvt. Ltd.

- Carborundum Industries, Murugappa group.

- International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI also at IITM Research park).

- Indira Gandhi Centre for Atomic Research, Kalpakkam

- Defence Metallurgical Research Laboratory, (DMRL – DRDO), Hyderabad

- Central Electrochemical Research Institute (CSIR-CECRI), Taramani, Chennai

Societal impact

- The activities proposed on defect engineered nanoparticles can attract CSR funding mainly for its suitability in application fields such as nanofillers, catalysis, water treatment, propellant for major aerosystems and fuel cell applications

- Mitigating this swelling and prolonging the fatigue life of the Si anodes by ‘defect engineering’ could positively impact the society. In this manner, Si anodes are expected to revolutionize the electronics industry.

- Interface engineered high strength steels and HEAs can become potential candidates for structural applications once the impact of Hydrogen induced embrittlement can be mitigated.

- By engineering the point defects in breeder ceramics, nuclear fusion technology can be developed.

Sustenance statement

- The unique nature of the characterization facilities being proposed for this CoE can enable value added research services at a premium.

- The CoE can offer research as a service (RaaS) that is comprehensive across length scales of characterization with correlative microscopy and backed by multi-scale computational models, which will attract researchers from academic as well as industry.

- The defect engineered materials design concept and the resulting materials database carry the scope of realizing materials exhibiting outstanding properties breaking the stereotypes.