Project

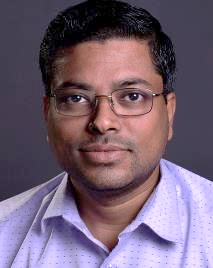

The project is divided into four essential work elements:

- Basic scientific research in waste processing for its use in low-carbon concrete systems

- Applied research leading to technology development

- An integrated test-bed for large-scale processes and visualization

- Organizational and policy research for large-scale technology adoption

E1: Basic scientific research in waste processing

E1-O1:

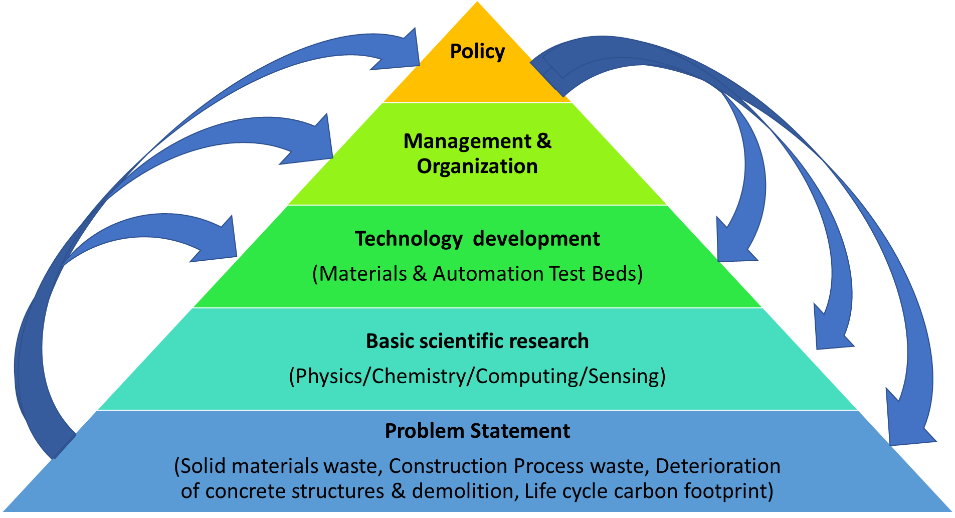

To develop low-energy techniques for physico-chemical processing and assess the suitability of waste for high-volume use in construction materials

E1-O2:

To develop a suitable sensor technology to automate the sorting and segregation of useful materials from the randomly mixed C&D waste

E1-O3:

To assess the use of the processed waste in producing concrete for special applications such as 3D printing, precast products, and pavements

E1-O4:

To study mechanical and durability characteristics of low-carbon concrete systems, and develop service life models for such systems in various environmental conditions

E1-O5:

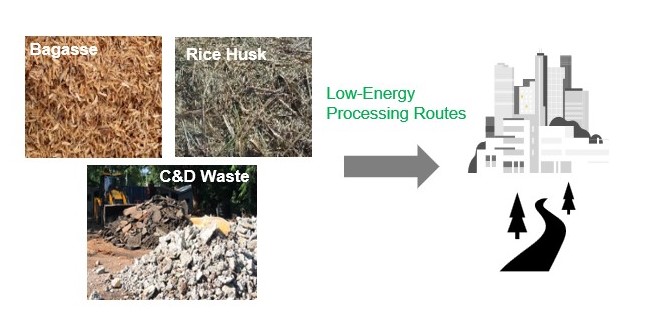

To develop a framework to assess the sustainability indicators of construction materials and construction processes using the principles of life cycle assessment

E2: Applied research leading to technology development

E2-O1:

To develop 3D printing technology for in-situ and precast construction of reinforced concrete and demonstrate robotic assembly

E2-O2:

To develop methods/models to relate performance of low-carbon concretes in the small-scale laboratory studies to large-scale field implementation studies

E2-O3:

To develop software to estimate service life and sustainability indices to enable faster material selection and durability-based design

E2-O4:

To develop low-cost, ‘lighter’, ready-to-use analytical tools and dashboards to minimize waste of time and materials from construction processes/practices and assess carbon footprint indices.

India’s First 3D Printed House (IITM-Tvasta Initiative)

E3: Integrated Test-Bed for Large-Scale Process and Visualization

E3-O1:

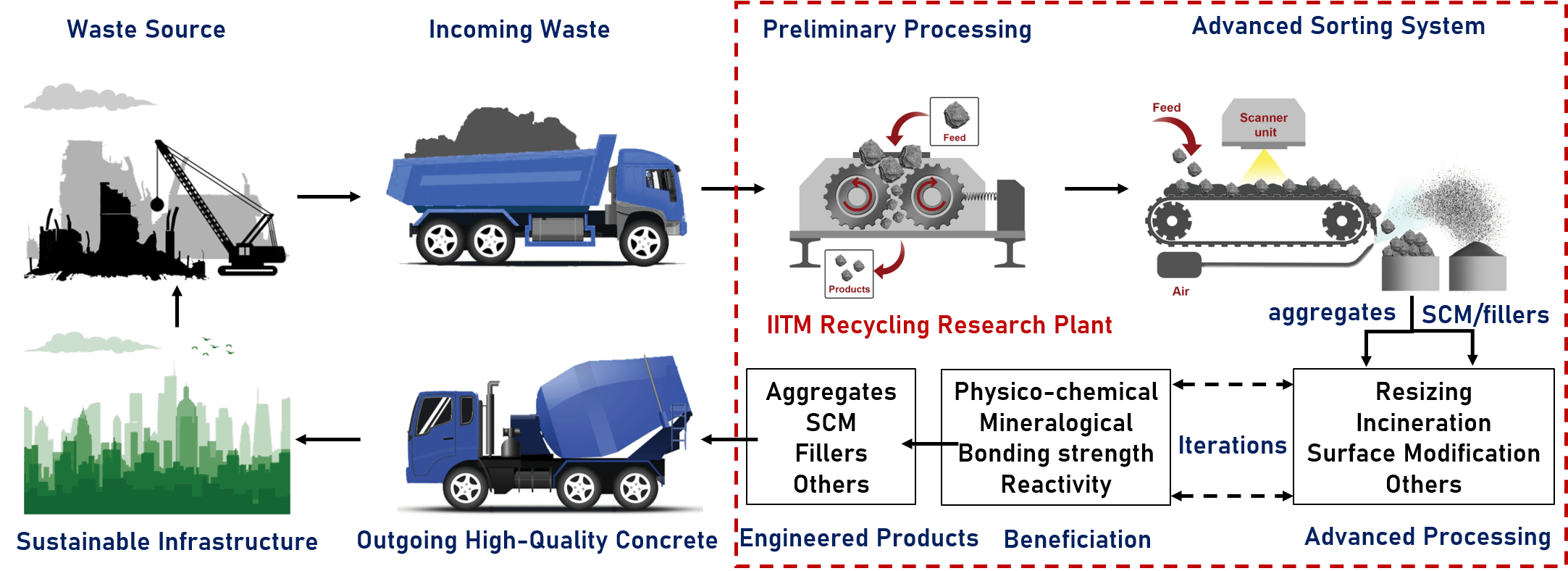

To design and install a physical recycling test-bed for automated screening and physico-chemical processing of various waste materials

E3-O2:

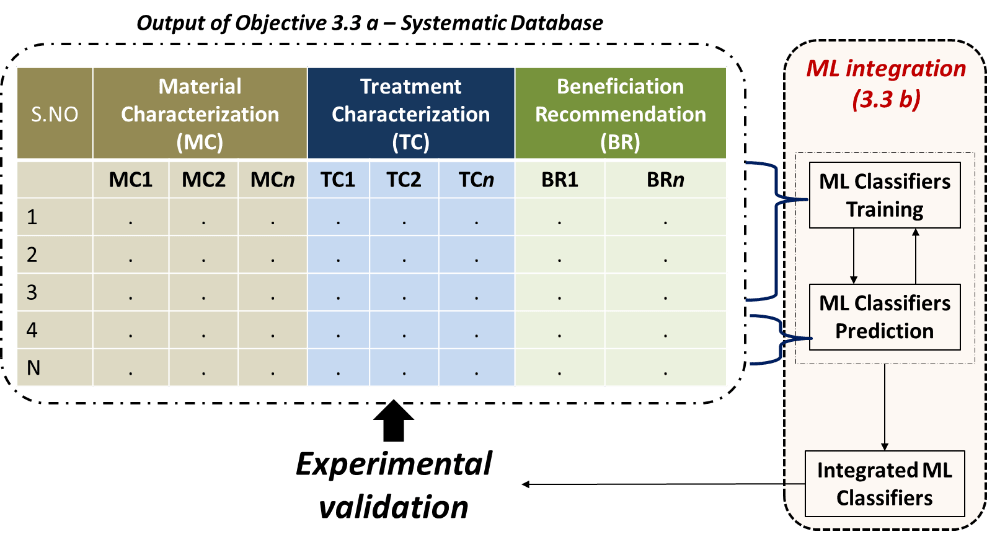

To integrate a Machine Learning (ML) analysis capability to predict the optimal usage of recycled material, based on a material characteristics database

E3-O3:

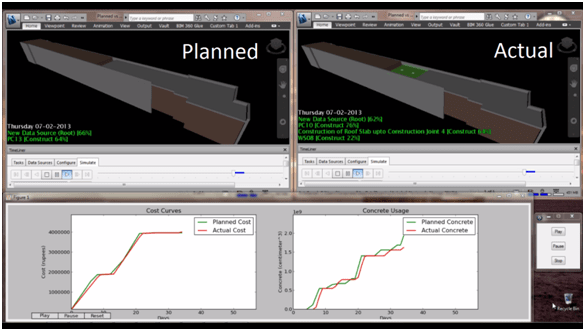

To develop a physical and AI-VR integrated testbed environment to identify optimal use of materials, simulate and optimize construction practices, and minimize carbon footprint

E3-O4:

To establish a simulation and game-based learning facility on management adoption strategies, organizational training, and specialty skill training on lean process.

nD BIM Simulations

E4: Organizational and policy research for large-scale technology adoption

E4-O1:

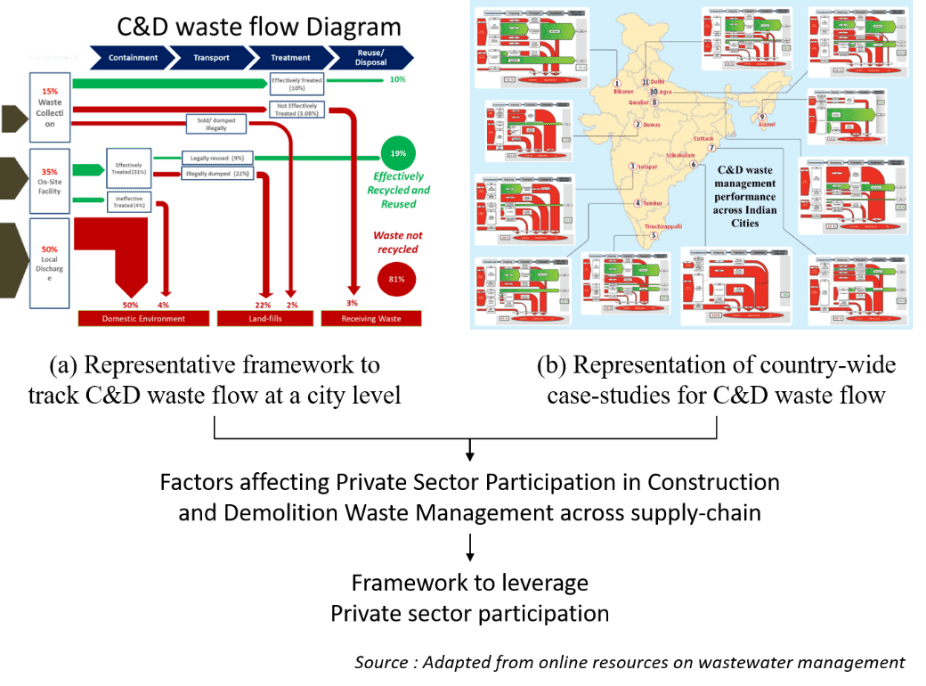

To develop national maps on current/future availability of waste materials

E4-O2:

To develop strategies for modifying organizational work practices to increase the adoption of lean construction practices

E4-O3:

To develop a framework to leverage private sector participation across supply-chain of concrete materials during the life-cycle of construction projects

E4-O4:

To develop Policy Notes for large-scale implementation of various waste utilization/reduction technologies

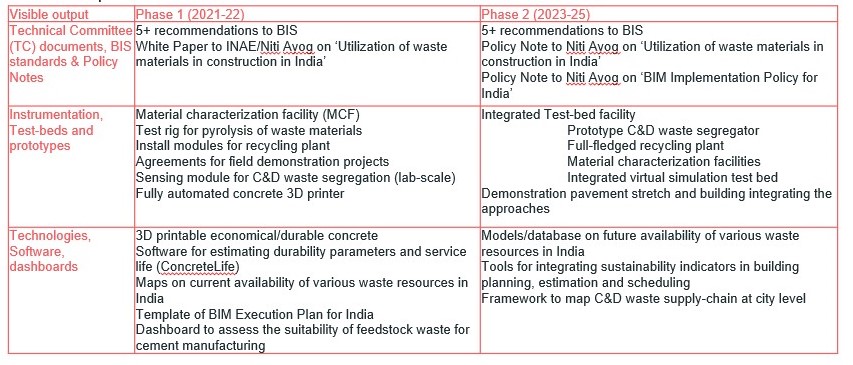

Expected deliverables of the research

Current status

- Tender process initiated for the purchase of equipment that are imported (Laser scanner).

- Specifications for an automated concrete 3D Printer for improving the speed of construction has been developed

- Started Undergraduate student projects on automation of waste segregation

- Design of the prototype of a robotic waste segregation system is under discussion

- Proposal on use of waste limestone from mines for concrete – to SERB (DST)

Collaborations

International Collaborations

- Prof. Elsa Olivetti, MIT, USA link

- Prof. Mark Alexander, University of Cape Town, South Africa link

- Prof. David Trejo, Oregon State University, USA link

- Prof. Taehwan Kim, University of New South Wales, Australia link

- Prof. Jochen Teizer, Aarhus University, Denmark link

- Prof. Quang Ha, University of Technology Sydney, Australia link

- Dr. Frederic Bosche, University of Edinburgh, UK link

- Prof. Dr.-Ing. Thomas Bock, Technical University of Munich, Germany link

- Dr.-Ing. Thomas Linner, Technical University of Munich, Germany link

- Prof Abhijit Mukherjee, Curtin University, Australia link

Conferences planned

- Engineering Project Organization, 2021, 2022

- International Symposium on Automation and Robotics in Construction (ISARC), 2021, 2022, 2023

- International Group of Lean Construction, 2022

- Construction Research Congress, 2022

- International Conference on Advances in Sustainable Construction Materials and Structures, 2021

- RILEM Convention and Conference, 2021, 2022

- Calcined Clay Conference, 2022

- American Concrete Institute Convention, 2022

- Transportation Research Board, 2022

- International System Dynamics Conference, 2022

- Workshop on Machine Learning for Construction Automation (https://www.cse.iitm.ac.in/~rupesh/events/mlca2021/)

- Workshop on Recycling of Concrete (UKIERI), 2022

Industrial collaborations

- SBI Foundation

- Tidewater

- LafargeHolcim

Societal impact

The work done under this RI project will impact several UN Sustainable Development Goals and therefore is likely to have direct societal impact. Our findings on utilizing and reducing waste in construction will lead to a direct reduction in green-house gas (GHG) emissions by reducing the consumption of virgin materials and optimizing waste (of time, materials and fuel) during transportation and energy-intensive construction processes. In addition to publishing in Q1 journals, we will also develop several policy briefs and play a role in formulating standards that will make the entire construction industry lean and carbon friendly. Apart from influencing society through policy we also hope to influence practitioners directly so that they can convert our discoveries into practice. This can be done in short and medium terms. We hope to catalyze a new breed of construction practitioners, who truly value sustainability alongside cost, time, and quality control. We will do this through summer schools, where we hope to train 100-150 professionals over 5 years, and through inviting practitioners to use our ‘test-bed’ to understand the various avenues to utilize waste in construction materials and virtually simulate their construction sites. In this way, we hope to educate and convince practitioners to boost adoption of waste minimization and management practices.

Sustenance statement

Several proposals to agencies like DST/SERB and industrial powerhouses such as LafargeHolcim and Reliance have been sent. In addition, we aim to seek large, programmatic funding. We were in discussions with L&T for setting up a centre for Large Infrastructure and hope to continue these discussions. We hope to leverage funds from L&T (and perhaps others in the construction industry through a centre-membership strategy) to both support the existing RI project and sustain it beyond its incubation period. Additionally, we have already attracted CSR funds (e.g. from SBI Foundation and Tidewater), and will continue to seek funding. We also hope to earn some consultancy revenue through executing projects through the centre. It is here that our test-bed could prove to be critical as it affords us the opportunity of renting the facility to a company to enhance their decision making on projects, therefore creating a stream of revenue. In addition, funds will also be collected through training programs and summer schools that are part of our work plan.

Technical/ Scientific Progress

New work done in the project

Achievements:

- Demonstration of the use of recycled aggregate initiated with CMRL

- BIM execution plan templates for Indian construction developed.

- Assessment of variation in characteristics of recycled aggregate completed and material suitable for construction has been identified.

- Apart from the solar energy utilization for RCA beneficiation (paper writing in progress), we have started working on evaluating the effect of the parent source on the performance of concrete paving mixes. Also, plans have been made to study the crushing mechanism.

New initiatives:

- Initiated discussions with agencies for mapping and large scale characterization of biomass ashes.

- Project related to low grade limestone use in concrete initiated; assessment of hydration characteristics of cementitious blends being performed.

- Characterization of coconut coir fibres ongoing, which will lead to the selection of fibres for use in concrete.

New funded projects:

- Use of low grade limestone in concrete (DST) - INR 53 Lakhs

- International project funded by the Global Cement and Concrete Association on LCA / LCCA of recycled concrete with several international partners from Hong Kong, Switzerland, China, and Brazil - INR 17 Lakhs

- DST Start Up Grant (Dr Surender Singh) Elucidating the Role of Cement-Asphalt-Aggregate Interaction on Failure and Durability of Rigid Pavements containing Reclaimed Asphalt Pavement Aggregates (SRG/2021/000582); Total Funding approved: 18.53 Lakhs

Infrastructure developments

Purchase orders issued for: (i) Rotary kiln; (ii) Incinerator; (iii) Online gas analyser; (iv) Aggregate image measurement system (item received); (v) Laser scanning system (item received); (vi) Workstations Bids under process for: (i) 3D printer; (ii) Sensors; (iii) Automated sorting equipment

Output

(i) Invited talks and conferences

- Manu Santhanam - Materials and Value Chains for Sustainable, Inclusive, and Resilient Urbanization in Africa, Jan 2021, organized by RILEM

- Kalyan Vaidyanathan, Benny Raphael, Aman Kumar, Makesh S and Yash Patil , Seamless Integration of Site Data into Planning and Monitoring of Construction Projects, In Proceedings of the Indian Lean Construction Conference, CEPT University, Ahmedabad, December 01–04, 2021 pp. 529-537.

- Sundararaman Krishnamoorthi and Benny Raphael , A Case Based Reasoning Approach for Selecting Appropriate Construction Automation Method, In Proceedings of 38th ISARC, Dubai, UAE, Nov, 2021, pp. 880-885. DOI: link

- ‘BIM for Accurate Quantity Estimation’, by Anil Sai Brahmadevi and Ashwin Mahalingam, presented at the Indian Lean Construction Conference 2021, held at Ahmedabad, Gujarat from Dec 1-4, 2021.

- ‘Quantity Estimation of Executed Works Using Image Analytics’ by Vikranth Gundapuneni and Ashwin Mahalingam, presented at the 38th ISARC conference,2021 at Dubai (conducted online).

- Piyush Chaunsali*, “Beneficial Utilization of Indian Biomass Ash in Eco-friendly Bricks”, International Conference: EM4SS'21 - Engineered Materials for Sustainable Structures, April 26, 2021.

- Atul Sharma, Anusha S. Basavaraj*, Piyush Chaunsali and Ravindra Gettu, “Environmental Impact of Calcium Sulfoaluminate Cement Manufacturing: An Indian Case Study”, 75th RILEM Week, International Conference on Advances in Sustainable Construction Materials and Structures, Merida, Mexico, Aug 2021.

- Selvam M, and Singh S (2021). “Development of a Rational Mix Design Procedure for Roller Compacted Concrete Pavements through Excess Paste Volume Method”, International Conference on Advances in Sustainable Construction Materials and Structures, Yucatan, Mexico, August 29 - September 3, 2021 (RILEM)

- Prajapati R., Gettu R., Stephen S. J., Singh Surender. “Properties of Concrete with Thermo-Mechanically Beneficiated Fine Recycled Aggregates”, International Conference on Advances in Sustainable Construction Materials and Structures, Yucatan, Mexico, August 29 - September 3, 2021(RILEM)

- Kosuri, M and Singh S. “Improving the Interfacial Bonding of Adhered Mortar with Recycled Concrete Aggregates for Roller Compacted Concrete Pavement Application”, International Conference on Advances in Sustainable Construction Materials and Structures, Yucatan, Mexico, August 29 - September 3, 2021 (RILEM)

- Anusha S. Basavaraj, Jayasuriya J. Surender Singh, and Ravindra Gettu. “Sustainability Assessment of Low-Volume Concrete Rural Roads made with Recycled Concrete Aggregate” International Conference on Advances in Sustainable Construction Materials and Structures, Yucatan, Mexico, August 29 - September 3, 2021 (RILEM)

- Selvam M, Dane R, and Singh S(2021). “Systematic Approach to Optimize Roller Compacted Concrete Pavements Mixes through Particle Packing Method”, 6th Conference of Transportation Research Group of India (CTRG)

- Selvam M, and Singh S (2022). “A Comprehensive Review of the Laboratory Compaction Techniques for Fabricating Roller Compacted Concrete Pavements ”, Transportation Research Board (101st Annual Meeting) (TRB)

(ii) Journal articles

- Sundararaman Krishnamoorthi and Benny Raphael, Performance Evaluation of Automated Construction Processes, accepted in Built Environment Project and Asset Management, 2021.

- Aparna Harichandran, Benny Raphael, and Abhijit Mukherjee, A Hierarchical Machine Learning Framework for Identification of Automated Construction Operations, DOI: 10.36680/j.itcon.2021.031, Journal of Information Technology in Construction, 26, pp. 591–623 2021. link

- Shantanu Bhattacherjee, Anusha S Basavaraj, A V Rahul, Manu Santhanam, Ravindra Gettu, Biranchi Panda, Erik Schlangen, Yu Chen, Oguzhan Copuroglu, Guowei Ma, Li Wang, Mirza Abdul Basit Beigh, and Viktor Mechtcherine, “Sustainable materials for 3D concrete printing,” Cement and Concrete Composites Vol. 122 (2021), 104156 (10.1016/j.cemconcomp.2021.104156).

- Vaasudevaa B. V., Dhandapani Y. and Santhanam M., “Performance evaluation of limestone-calcined clay (LC2) combination as a cement substitute in concrete systems subjected to short-term heat curing,” Construction and Building Materials Vol. 302 (2021), 124121 (10.1016/j.conbuildmat.2021.124121).

- M. Selvam, M., Solomon Debbarma, Surender Singh, and Xijun Shi (2022), “Utilization of alternative aggregates for roller compacted concrete pavements–A state-of-the-art review” Construction and Building Materials, Elsevier. Vol. 317, DOI: 10.1016/j.conbuildmat.2021.125838

- M. Selvam, and Surender Singh (2022), “A State-of-the-Art Review on Material Selection and Mixture Proportioning Methods for the Sustainable Roller Compacted Concrete Pavements” Journal of Materials in Civil Engineering, American Society of Civil Engineers, ASCE, DOI: 10.1061/(ASCE)MT.1943-5533.0004325 (Accepted)

(iii) Workshops / Symposium organized RILEM PhD Symposium on Technologies for Low Carbon Lean Construction, Sep 2021 (online) International Workshop on Advances in Technologies for Low Carbon Lean Construction, Dec 2021 (in person)

(iv) Webinars organized “Utilization of Off-Spec Fly Ash for Low Carbon Concrete” by Prof. Farshad Rajabipour (Penn State University, USA) on Sep 21, 2021.

Mobility

Visits planned for PI, co-PIs, international collaborators and students (both inbound and outbound)

(i) Prof Mark Alexander from Univ of Cape Town and Prof Yunus Ballim from Univ of Witwatersrand are expected to visit late Jan / early Feb 2022 (ii) Prof Ram Rajagopal from Stanford will visit IITM in May/June 2022. (iii) Dr. Taehwan Kim, University of New South Wales, Australia (Planned for Summer 2022)

Relationship

Industrial Engagement

Projects implementing ideas from TLC2

- CMRL and Schwing Stetter for demonstration of recycling of demolished concrete

- National Capital Region Transport Corporation (NCRTC) on lean construction

- Saint Gobain Research India on development of alternative reinforcement for Textile Reinforced Concrete

- Holcim on development of binders for glass reinforcement

Capacity building on Low Carbon and Lean Construction

- National High Speed Rail Corporation Limited (NHSRCL)

- L&T Construction

- WeStart India

- Confederation of Indian Industry (CII)

- Kerala Highway Research Institute (KHRI)

- Govt of Uttarakhand

Mentorship of start-ups

- Strufocon (Kochi) - for durability of new and existing reinforced concrete structures

- Tvasta Manufacturing Solutions - for 3D printing and automation

- SLABS Engineering - for 3D volumetric precast construction

- Modulus Housing - for innovative foldable housing solutions

Standards and policies

- Involvement in BIS Committees on Concrete (CED2), Precast Construction (CED32), Reinforcement (CED54)

- Representation in the committee developing the Tamil Nadu urban and rural housing policy

University Engagement

MOUs

- With Univ of Leeds for joint PhD guidance

Joint proposals and collaborations

- Curtin University, Australia - (proposal) on use of mine tailings in construction

- Brunel University, UK - on recycled concrete

- EPFL Switzerland - on sustainable binder systems for low carbon construction

- RWTH Aachen, Germany - on modular sewage treatment plants for rural areas

- CSTB, France - on supply chains for low carbon lean construction

Discussions

- With University College London regarding collaborative projects on circular economy

- With Imperial College London, Politecnico di Milano, and TU Delft - on corrosion and its control

- With Georgia Tech Univ and Stanford Univ on digitalization for sustainability

Updates

Relevant Updates

- Applications for International Post Docs being currently evaluated. Three potential candidates shortlisted.

- Advertisement for international PhD students currently being circulated - plan is to have them join in the July 2022 session.