Project

Drying or evaporation is a diffusive process wherein the constituent molecules are lost from the surface of a liquid as vapour and become part of the gaseous phase. The evaporation of volatile liquids is a commonly and ubiquitously observed process. The evaporation of water from various water bodies on the surface of earth is essential for the formation of clouds. So is the case for the water cycle which is relevant to the very existence of life on earth. The evaporative loss of water from the surface of earth has important consequences on propelling renewable energy sources such as wind and hydropower. The evaporation of simple and complex fluid drops can lead to a myriad of structures and patterns of varying length scales.

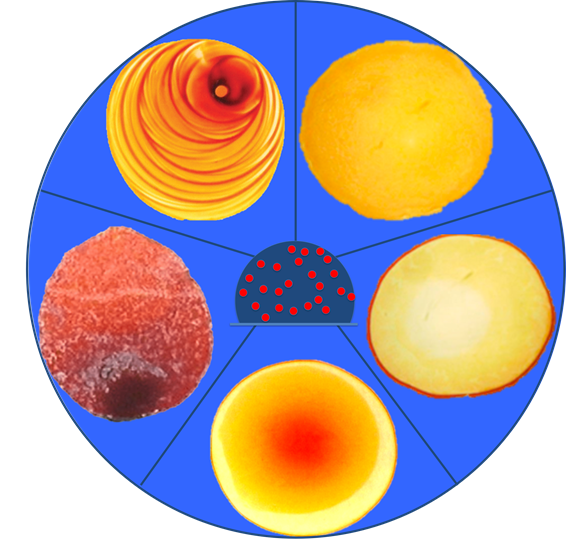

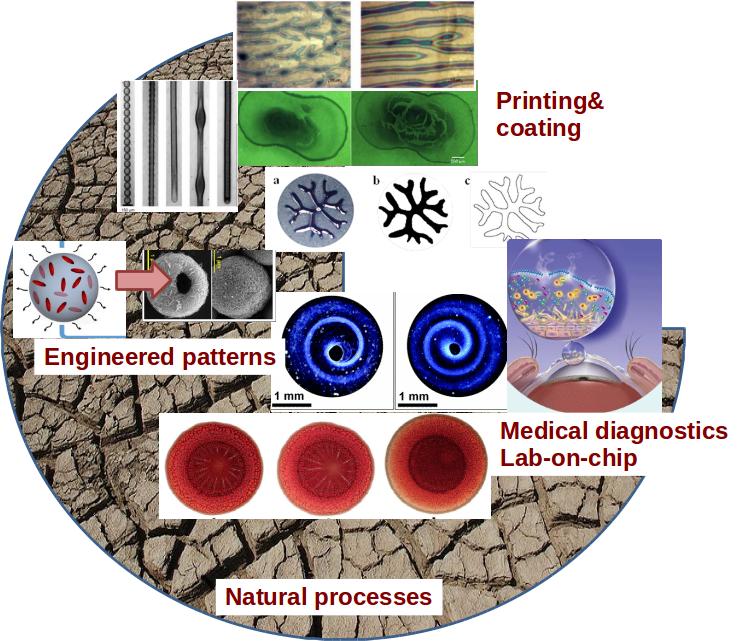

Myriad of engineering, natural and biomedical processes and applications which depend upon evaporation and drying of complex fluids

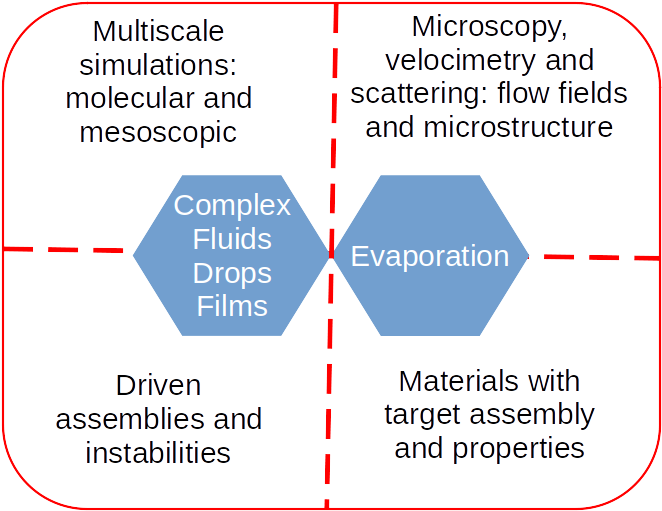

Evaporation is a standard unit operation in materials preparation. Similarly, over the last decade, significant research has been undertaken in assembly, microstructure and behaviour of complex fluids and soft matter. This project is focused on bringing together science and engineering of evaporation on one hand, and the mechanics and manipulation of complex fluids on the other. The novelty of this proposal lies in the identification of evaporation as a key mechanism of manipulating structure in drops and films of complex fluids:

Not only to natural events, evaporation is also central to industries. Most often, industrial and technologically/biomedically important processes involve evaporation of drops or thin films containing (i) dissolved solutes such as salts, proteins, etc. (ii) non-volatile solutes such as nanoparticles, colloids, polymers, surfactants or their mixtures. For example, inkjet printing, which is gaining importance in the fabrication of optoelectronic devices, lab-on-chip applications etc., involves – drop formation, ejection, drop deposition, coalescence and drying on solid surfaces. Finally, evaporation of solvent molecules from the ink drops leading to a residue of non-volatile components on the solid surface. It is the final distribution of solute particles that dictate the efficacy of ink jet printing or for that matter any process involving drying of drops containing dispersed material. Evaporation of drops containing one or more non-volatile matter assumes importance in food technology, pharmaceutical industries, personal care industries, agricultural sector, coating technology and fabrication of functional devices. The evaporation of bio-fluids has been an active area of research in recent years. To this end, there has been emphasis on the evaporation of complex fluid drops of biological origin, namely, blood, respiratory fluids, synovial fluid present in the cavities of synovial joints. These investigations have been typically used as simple tests for identifying disease conditions in persons with abnormal health symptoms as well as in determining the spreading ability of air-borne diseases.

The specific problems on which the research work will be carried include:

- Evaporation of colloidal dispersions in complex configurations

- Low-dimensional self-assembly of soft colloids via solvent evaporation

- Coalescing droplets and instabilities during drying leading to patterns and defects

- Drying of dispersions of non-spherical particles, binary colloids, molecular solutions and polymers

- Evaporation of biological fluids for diagnosis and biomedical interventions

Expected deliverables of the research

The proposed research is very likely to yield advancements in basic science of complex fluid drops in general and drying related phenomena in particular. The research outcomes will be key to development of disruptive technologies in flexible electronics, inkjet and screen printing, medical diagnosis, photonic crystals, batteries, multi-functional polymer-nanoparticle composites and so on. The group of PIs involved in the project have complementary expertise both in theory/computation and experimental methods. PIs have already established sustained collaboration with leading researchers in the field by mutual visits and bilateral research projects. If the proposed research is funded, the bilateral relations with the international community can be reinforced and a broader visibility may be achieved.

The research outcomes are likely to be published in international peer reviewed journals (IF > 6), including but not limited to Physical Review Letters, Journal of American Chemical Society, Nature Communications, Nanoscale, Sustainable Chemistry, Journal of Colloids and Interface Science, Macromolecules etc.

Current status

Recent Publications:

Further Insights into Patterns from Drying Particle Laden Sessile Drops Dinesh Parthasarathy, Sumesh P. Thampi, Parag Ravindran, and Madivala G Basavaraj Langmuir 2021 37 (14), 4395-4402 DOI: 10.1021/acs.langmuir.1c00512

Post Docs:

- Dr. Amol Subhedar

- Dr. Garima Mishra

PhD/MS Students:

- Lohesh Kumar

- Merin Jose

- Dinesh Parthasarathy

- Sanket Kumar

- Priyanka Pushparajan

Collaborations

International Collaborations

- Prof. Anand Yethiraj, Physics and Physical Oceanography, Memorial University of Newfoundland link

- Prof. Arun Ramachandran, Department of Chemical Engineering and Applied Chemistry, University of Toronto, Canada link

- Prof. Ignacio Pagonabarraga, European Centre of Atomic and Molecular Computations, EPFL, Switzerland link

- Prof. Jan Vermant, Soft Materials, ETH Zurich link

- Prof. Julia M Yeomans, The Rudolf Peierls Centre for Theoretical Physics, University of Oxford, UK link

External international site

International education programs

- A two day event on the pedagogical aspects and emerging trends in complex fluid drops research is planned in the 4th week of July 2021. The details will be update soon.

Industrial collaborations

- We are currently working towards signing CDA between the PIs and some industry partners

Societal impact

The proposed work will have implications on several sections such as health care, water preservation and industry. The research outcomes are very likely to improve our strategies to prevent evaporative losses of larger water bodies such as lakes, ponds and reservoir water. Interfacial engineering of water-air interfaces by judicious choice of materials can save large amount of water from evaporative losses. Another area is effective and minimal use of pesticides in agriculture practice. By understanding drying of drops and thin-films on superhydrophobic surfaces like crop leaves, optimal design of spraying nozzle can be achieved that optimal use of pesticides. The research outcomes may lead to design of DIY-diagnostic kits for personal use at home, lab-on-chip kits for various diagnostic applications. Other implications include improved understanding of detergency (stain removal), optimal drying conditions for battery electrolytes, removal of oil-spillages in oceans, etc. These processes that affect society and environment can be of potential interest of corporate business, and may attract additional funding and visibility.

Sustenance statement

The PIs recognize that many bilateral projects sponsored by DST (Indo-German, Indo-Japan, Indo-Norway, Indo-France, Indo-UK (UKIERI), Indo-US (IUSSTF) etc) will be potential funding source to meet our international presence, exchange of students between institutes, and more importantly maintenance of the equipment procured through COE funding. We have a Indo-Norway project sanctioned for the period 2020 - 2023 with NTNU, Norway, which allows exchange of PI and PhD students between IIT-M and NTNU.

Another strategy to stay in the internal map is by making sabbatical visits (short or long) to our international collaborators’ group. These visits are possible by various funding sources such as Fulbright, Humboldt, JSPS fellowships, to name a few. Two of the PIs have already availed DAAD fellowships to spend 2-3 months in Germany to visit TU-Berlin, Dusseldrof Univ., and Forschungszentrum Julich.

We shall also seek funding and collaboration with industrial partners, in particular, from paint, agriculture, pharmaceutical, diary and FMCG sectors. To enable the placement of PhD and postdoc scholars, industrial consortiums will be set up for regular meetings with industry and academia. We shall also reach out to alumni from our groups to sponsor research and endowments of visiting chairs.

References

Technical/ Scientific Progress

New work done in the project

Numerical simulation of drying of drops:

We have undertaken the numerical study of solute particle deposition in drying drops. The flow dynamics in these systems is governed by factors that include evaporation rate, pinning effects, and gravity. How these factors affect the lifetime of a drop is a question of technological importance. We use lattice Boltzmann method to solve the relevant fluid dynamical equations. To begin with, the two-phase flow numerical model is validated against benchmarks to test its ability to handle contact with solid surfaces, especially contact line pinning, and a prescribed evaporation flux. To delineate the various factors affecting the evaporation rate, we study the evaporation process in the kinetic mode, where the evaporation flux is constant across the drop surface. The use of the kinetically controlled mode of evaporation removes the need for solving for vapor concentration. This assumption allows using a smaller computational grid while still preserving the evaporation modes (i.e., constant contact angle and constant contact radius mode). In the regime Bond number (Bo<1), we find that the deformed surface area of the drop depends upon the magnitude of the non-axisymmetric component of the gravity rather than its sign. For a given Bond number, the drop deformation is highest when the gravity vector points parallel to the solid surface. The drop evaporation rate, under the kinetically controlled evaporation, follows the same trend. Further, we demonstrate that the lower limit of the hysteresis window determines the evaporation rate for a given initial shape of the drop. Increase in the difference of initial receding contact angle and the lower limit of the hysteresis window increases the evaporation time in the pinned state. We support and compare these observations with previous analytical and numerical works. The results of this work are being compiled in a manuscript [1].

The second part of the work is aimed at understanding the effect of gravity on particle deposition patterns. The starting point of work is a theoretical treatment based on the variational formulation [2]. We are extending this work to include the effect of gravity by using Stoke’s settling velocity for the depositing particles. The contribution of the gravitational potential of the drop and on the fluid velocity will be added in the next steps. Even in this simplified model, preliminary studies indicate the influence of gravity on the particle deposition pattern. This work is in progress. In addition, we are use of finite element method-based solver COMSOL Multiphysics to solve the coupled governing equations with the relevant boundary and initial conditions to simulate drying drops. The laminar flow, heat transfer in fluids and the transport in dilute species modules have been solved using a fully coupled time-dependent solver PARDISO. The time-discretization is done using the Generalized alpha scheme, which is an implicit, second order accurate method. The moving mesh methods using the Augmented Lagrangian Eulerian (ALE) scheme have been employed herein to track the movement of the interface during the evaporation process.

A. Subhedar, G. Mishra, S. P. Thampi and M. G. Basavaraj, Drop evaporation modes in the presence of gravity: A lattice Boltzmann study, in preparation

X. Man and M. Doi, Ring to Mountain Transition in Deposition Pattern of Drying Droplets, Physical Review Letter 116, 066101 (2016)

Experimental study of drying of drops:

We have made considerable progress in the following aspects of proposed work:

- Investigation of drop evaporation on inclined surfaces

- Evaporation of milk drops as novel route to detect adulteration

- Imaging of internal flows and particle mobility in drying drops

- Experimental study of tear films

Infrastructure developments

We have initiated purchase procedure for two instruments and global tenders for 3 instruments are being prepared.

Output

Conference Participation:

92nd Society of Rheology Meeting October 10-14, 2021 – Bangor, Maine, USA

Soft Matter : Young Investigators e-Meet 2021 (e-SMYIM 2021) 14 - 16 October, 2021

Complex Fluids 2021, 13th to 15th December 2021

Webinars:

- Prof. Ronald Larson, Chemical Engineering, University of Michigan: Simple, Efficient Material Deposition Using Droplet Drying: Transport Modeling and Applications. 15th July 2021

- Prof. Mahesh S Tirumkudulu, Department of Chemical Engineering, IIT Madras: Capillary Induced motion of particles in thin liquid films. 16 September 2021

- Prof. Anand Yethiraj, Physics and Physical Oceanography, Memorial University of Newfoundland: Dipolar Depletion: A tunable colloid-polymer model system. 9 December 2021.

Research Articles:

- Dinesh Parthasarathy, Sumesh P. Thampi, Parag Ravindran, and Madivala G. Basavaraj. Further Insights into Patterns from Drying Particle Laden Sessile Drops. Langmuir 37 (14), 4395–4402 (2021).

- M Jose, Madivala G. Basavaraj, Dillip K. Satapathy. Evaporative self-assembly of soft colloidal monolayers: The role of particle softness on microstructure. Soft Matter 17, 7921–7931 (2021).

- P Logesh Kumar, Sumesh P Thampi, Madivala G. Basavaraj. Patterns from Drops Drying on Inclined Substrates. Soft Matter 17, 7670–7681 (2021).

- Sanket Kumar, Madivala G. Basavaraj, Dillip K. Satapathy. Formation and suppression of secondary cracks in deposits of colloidal ellipsoids. Submitted to Colloids and Surfaces A (2021).

Mobility

Visits planned for PI, co-PIs, international collaborators and students (both inbound and outbound)

Prof. Sanat Kumar, Bykhovsky Professor of Chemical Engineering, Columbia University (Dec 2021 to Jan 2022)

Hamant Kumar PhD Student, IIT Madras is to visit Prof. Arun Ramachandran - Laboratory of Complex Fluids, Chemical Engineering & Applied Chemistry, University of Toronto, Canada in April 2022

Relationship

Industrial Engagement

We have initiated dialogues with:

- Hindustan Unilever Research Centre

- Saint-Gobain Research (SGR) India

- Axxelent Pharma Science Pvt. Ltd.

University Engagement

Collaboration with Prof. Arun Ramachandran - Laboratory of Complex Fluids, Chemical Engineering & Applied Chemistry, University of Toronto, Canada

Collaboration with Prof. Anand Yethiraj, Physics and Physical Oceanography, Memorial University of Newfoundland, Canada

Collaboration with Prof. Ruth Cardinaels, Department of Chemical Engineering, KULeuven, Belgium